High efficiency requires excellent processes

Achieving high efficiency is a common business objective, particularly during challenging economic conditions (although it shouldn’t be undermined during more favourable times either). More than often, efficiency objectives are stated in financial terms and can be even synonymous with cost-saving programs.

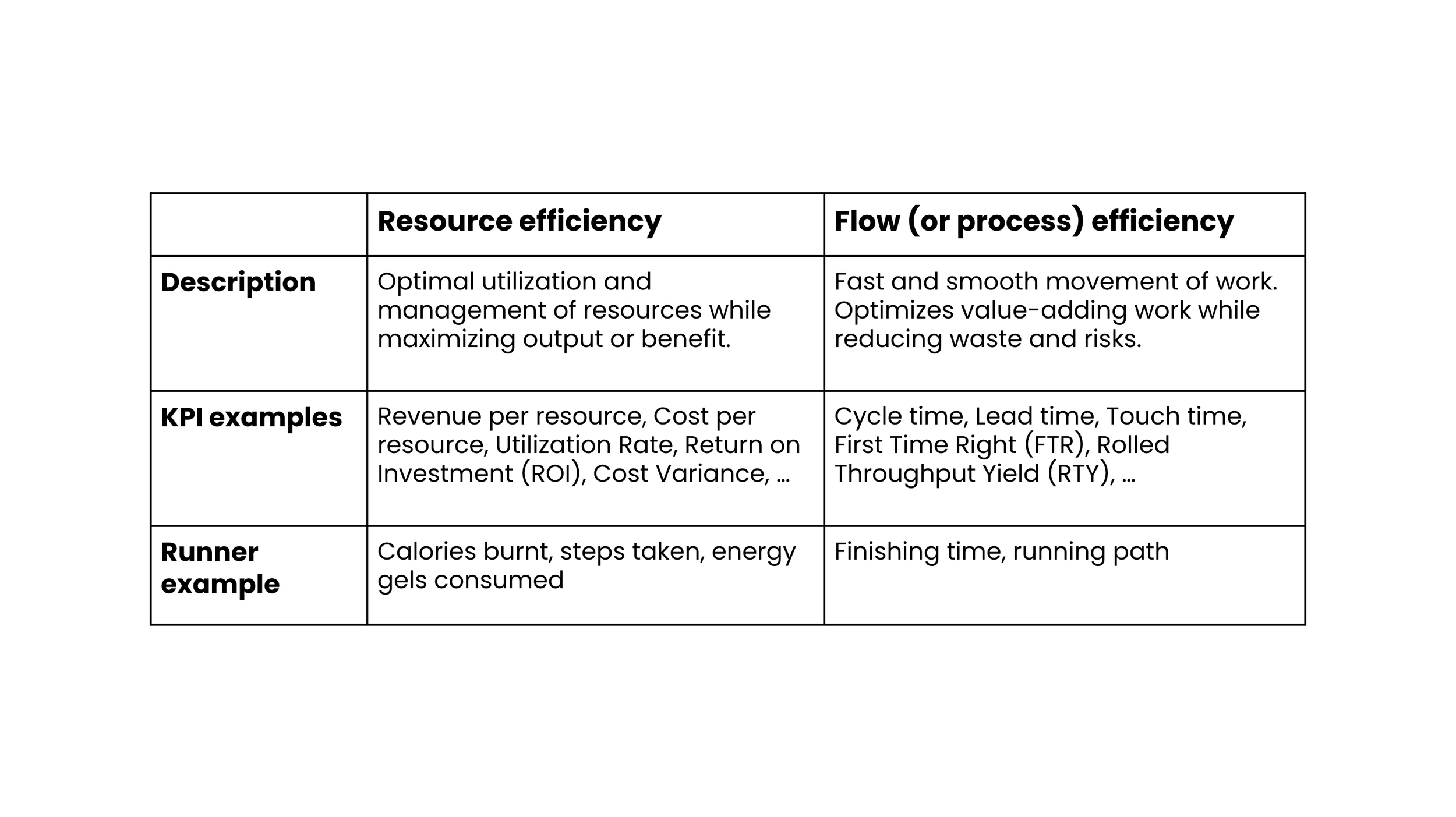

This type of finance-oriented efficiency is typically referred to as resource efficiency. Paradoxically, to achieve high resource efficiency or get the most out of the cost-saving programs, another type of efficiency should be increasingly emphasised. This type of efficiency is known as flow efficiency.

“Efficiency” = resource efficiency + flow efficiency

In general terms, processes (essentially just a fancy term for work) turn resources into customer value, of which customers are usually willing to pay for. However, not all work contributes as much to the final value, and two organisations with the same resources are rarely able to turn them into equally valuable outcomes.

Focusing on resources alone is like buying new golf clubs and assuming it replaces training. On the other hand, focusing on purely the process is not great either, good golf clubs still can make a difference in the right hands. It is clear that organisations that strive for high efficiency in general should probably strive for it in both categories.

Build a process improvement project portfolio with cost-saving requisites

From an efficiency perspective, “Lean” would be defined as the state where we have both high resource and flow efficiency. But how to get there?

Matrix: The relationship between resource efficiency and flow efficiency from “This is Lean” by Niklas Modig and Pär Åhlström

For various good and not-so-good reasons, resource efficiency metrics are often more widely used than flow efficiency metrics, especially the higher up we go in the organisational ladder. A resource-focused organisation is primarily led through unit-specific budgets and financial targets. The complexity arises in proportionately allocating these targets across various departments, often depending on historical cost trends or specific resource efficiency metrics. Managers are often tasked with educated guesses to balance various resources, which can be demanding. Biggest savings or efficiency improvements are often found between the various organisational silos. This is the “Efficient islands” state where many companies are stuck.

Processes and quality management are keys to unlocking new efficiency improvements. The increasing organisation around end-to-end flows spanning various organisational departments and units reduces the silos and improves the quality of your products and services. By establishing a process improvement project portfolio, where each project is explicitly linked to specific financial or risk mitigation goals in addition to the process flow improvement objectives, we combine the best of the two worlds.

Good processes reduce the need for resources and optimize their allocations. Good processes also enable higher automation rates, which can be a significant resource efficiency and quality leap (it is not usually a good idea to automate bad processes). This type of improvement portfolio tends to gradually improve organisations according to the arrow in the matrix. This is what continual improvement towards the “Lean” state of high efficiency, high customer and employee satisfaction, and overall quality means.